Please contact us in time

hlzgmach@outlook.com citichc@outlook.com +86-0379 60208535 Online Message1, the characteristics of the rod mill is in the process of grinding, grinding medium and ore line contact, so it has selective grinding effect;

2, the product particle size is more uniform, less over-crushed ore particles;

3. When used for rough grinding, the handling capacity of the rod mill is greater than that of the ball mill of the same specification, and vice versa;

4, stable operation, energy saving and consumption reduction, high output.

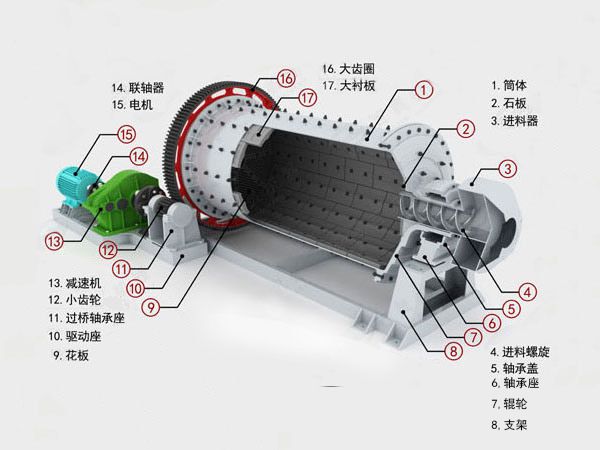

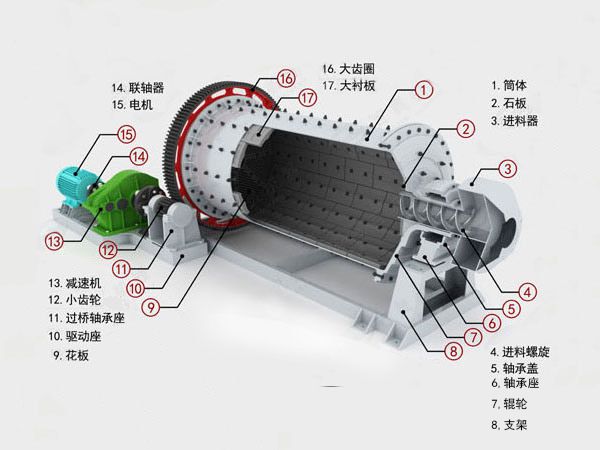

Rod mill is asynchronous motor through the gear reducer and small gear coupling, turns around the big gear reduction, directly driven rotary rotary, barrel inner is equipped with the appropriate grinding medium - steel rods, grinding medium under the action of centrifugal force and friction force, to manufacture materials by feeding department continuously into the barrel inside, are controlled by the movement of grinding medium crushing, And through the overflow and continuous feeding force of the product out of the machine to carry out the next process.

Rod mill is driven by motor through reducer and surrounding big gear reduction drive or by low speed synchronous motor directly through the surrounding big gear reduction drive, drive cylinder rotation. The cylinder is equipped with a suitable grinding medium - steel rod. Under the action of centrifugal force and friction, the grinding medium is lifted to a certain height and falls in a state of drop or discharge. The grinding material enters the cylinder continuously from the feeding port, is crushed by the moving grinding medium, and the product is discharged out of the machine through overflow and continuous feeding force to carry out the next process operation.

When the product particle size is required to be 80% less than 2.0% to 0.5mm, the general use of rod mill, rod mill product particle size, generally not more than 4.7mm, small not less than 0.4mm, rod mill feeding particle size is 80% less than 20mm to 4mm, feeding particle size can also be up to 50mm. Due to the material and other reasons of the grinding rod, the length of the grinding rod can not exceed 6.1 meters, otherwise it will cause bad consequences such as disorderly rod, so the specification of the rod machine has not exceeded the specification 4.6×6.3 meters.

When the ore is fed into the rod mill, the coarse particles are at the feeding end and the fine particles are at the discharging end: therefore, the rod group cannot be completely parallel and tilted in operation, which is also a reason for limiting the length of the grinding rod.

Rod mill crushing ratio of 15:1 to 20:1, most of the conventional grinding process of foreign concentrator is composed of crusher, rod mill, ball mill, China's concentrator using rod mill is not much, ball mill to ore particle size is high, resulting in energy consumption, grinding medium consumption, lining plate consumption, etc. Rod mill because the grinding rod is in line contact, so the large material first by grinding, with selective grinding effect so the product particle size range is narrow, uniform product particle size, less over grinding phenomenon, grinding efficiency is high

型号 |

筒体直径 |

筒体长度 |

电机型号 |

电机功率 |

电机转 |

长 |

宽 |

高 |

处理能力(t/h) |

有效容 积(m3) |

重量 |

(mm) |

(mm) |

(kW) |

数(r/min) |

(mm) |

(mm) |

(mm) |

(kg) |

||||

MBY 0918 |

900 |

1800 |

Y225M-8 |

22 |

730 |

4980 |

2370 |

2020 |

0.62~3.2 |

0.9 |

5700 |

MBY 0924 |

900 |

2400 |

Y250M-8 |

30 |

730 |

5670 |

3280 |

2020 |

0.81~4.3 |

1.2 |

5880 |

MBY 1224 |

1200 |

2400 |

Y280M-8 |

45 |

730 |

6450 |

2800 |

2500 |

0.4~4.9 |

2.28 |

12308 |

MBY 1530 |

1500 |

3000 |

JR125-8 |

95 |

725 |

7935 |

3185 |

2280 |

5 |

19990 |

|

MBYg 2130 |

2100 |

3000 |

JR136-8 |

180 |

735 |

8122 |

4220 |

3073 |

14~35 |

9 |

42123.5 |

MBYg 2136 |

2100 |

3600 |

JR137-8 |

210 |

735 |

8958 |

4320 |

3025 |

43~61 |

10.8 |

45800.5 |

MBYg 2430 |

2400 |

3000 |

JR138-8 |

280 |

735 |

9004.5 |

4836.4 |

3490 |

11.5 |

55795 |

|

MBYg 2732 |

2700 |

3200 |

JR157-8 |

320 |

750 |

10509 |

5000 |

3620 |

15.7 |

83110 |

|

MBYg 2736 |

2700 |

3600 |

JR158-8 |

380 |

743 |

10764 |

5750 |

3620 |

32~86 |

17.7 |

1, the characteristics of the rod mill is in the process of grinding, grinding medium and ore line contact, so it has selective grinding effect;

2, the product particle size is more uniform, less over-crushed ore particles;

3. When used for rough grinding, the handling capacity of the rod mill is greater than that of the ball mill of the same specification, and vice versa;

4, stable operation, energy saving and consumption reduction, high output.

Rod mill is asynchronous motor through the gear reducer and small gear coupling, turns around the big gear reduction, directly driven rotary rotary, barrel inner is equipped with the appropriate grinding medium - steel rods, grinding medium under the action of centrifugal force and friction force, to manufacture materials by feeding department continuously into the barrel inside, are controlled by the movement of grinding medium crushing, And through the overflow and continuous feeding force of the product out of the machine to carry out the next process.

Rod mill is driven by motor through reducer and surrounding big gear reduction drive or by low speed synchronous motor directly through the surrounding big gear reduction drive, drive cylinder rotation. The cylinder is equipped with a suitable grinding medium - steel rod. Under the action of centrifugal force and friction, the grinding medium is lifted to a certain height and falls in a state of drop or discharge. The grinding material enters the cylinder continuously from the feeding port, is crushed by the moving grinding medium, and the product is discharged out of the machine through overflow and continuous feeding force to carry out the next process operation.

When the product particle size is required to be 80% less than 2.0% to 0.5mm, the general use of rod mill, rod mill product particle size, generally not more than 4.7mm, small not less than 0.4mm, rod mill feeding particle size is 80% less than 20mm to 4mm, feeding particle size can also be up to 50mm. Due to the material and other reasons of the grinding rod, the length of the grinding rod can not exceed 6.1 meters, otherwise it will cause bad consequences such as disorderly rod, so the specification of the rod machine has not exceeded the specification 4.6×6.3 meters.

When the ore is fed into the rod mill, the coarse particles are at the feeding end and the fine particles are at the discharging end: therefore, the rod group cannot be completely parallel and tilted in operation, which is also a reason for limiting the length of the grinding rod.

Rod mill crushing ratio of 15:1 to 20:1, most of the conventional grinding process of foreign concentrator is composed of crusher, rod mill, ball mill, China's concentrator using rod mill is not much, ball mill to ore particle size is high, resulting in energy consumption, grinding medium consumption, lining plate consumption, etc. Rod mill because the grinding rod is in line contact, so the large material first by grinding, with selective grinding effect so the product particle size range is narrow, uniform product particle size, less over grinding phenomenon, grinding efficiency is high

型号 |

筒体直径 |

筒体长度 |

电机型号 |

电机功率 |

电机转 |

长 |

宽 |

高 |

处理能力(t/h) |

有效容 积(m3) |

重量 |

(mm) |

(mm) |

(kW) |

数(r/min) |

(mm) |

(mm) |

(mm) |

(kg) |

||||

MBY 0918 |

900 |

1800 |

Y225M-8 |

22 |

730 |

4980 |

2370 |

2020 |

0.62~3.2 |

0.9 |

5700 |

MBY 0924 |

900 |

2400 |

Y250M-8 |

30 |

730 |

5670 |

3280 |

2020 |

0.81~4.3 |

1.2 |

5880 |

MBY 1224 |

1200 |

2400 |

Y280M-8 |

45 |

730 |

6450 |

2800 |

2500 |

0.4~4.9 |

2.28 |

12308 |

MBY 1530 |

1500 |

3000 |

JR125-8 |

95 |

725 |

7935 |

3185 |

2280 |

5 |

19990 |

|

MBYg 2130 |

2100 |

3000 |

JR136-8 |

180 |

735 |

8122 |

4220 |

3073 |

14~35 |

9 |

42123.5 |

MBYg 2136 |

2100 |

3600 |

JR137-8 |

210 |

735 |

8958 |

4320 |

3025 |

43~61 |

10.8 |

45800.5 |

MBYg 2430 |

2400 |

3000 |

JR138-8 |

280 |

735 |

9004.5 |

4836.4 |

3490 |

11.5 |

55795 |

|

MBYg 2732 |

2700 |

3200 |

JR157-8 |

320 |

750 |

10509 |

5000 |

3620 |

15.7 |

83110 |

|

MBYg 2736 |

2700 |

3600 |

JR158-8 |

380 |

743 |

10764 |

5750 |

3620 |

32~86 |

17.7 |