Please contact us in time

hlzgmach@outlook.com citichc@outlook.com +86-0379 60208535 Online MessageCement ball mill because of its product size, shape, more suitable for the application of cement grinding, cement hydration and late strength improvement has a great advantage, so cement ball mill is widely used in cement grinding. There are 35 specifications and models of the cement ball mill product barrel diameter from 1.2m to 4.2m, supporting motors from 55KW to 3530KW, a single cement ball mill can meet the grinding of 1.4-87t cement products per hour, if used together with roller press, the capacity will be greatly improved.

1, high grinding efficiency, low energy consumption;

2, the fineness of the product is uniform, and the product is smooth;

3, small vibration, low noise, good sealing equipment, no dust spillover, clean environment, meet the requirements of environmental protection;

4, can design and manufacture special cement mill according to the user's different needs of grinding fineness and output.

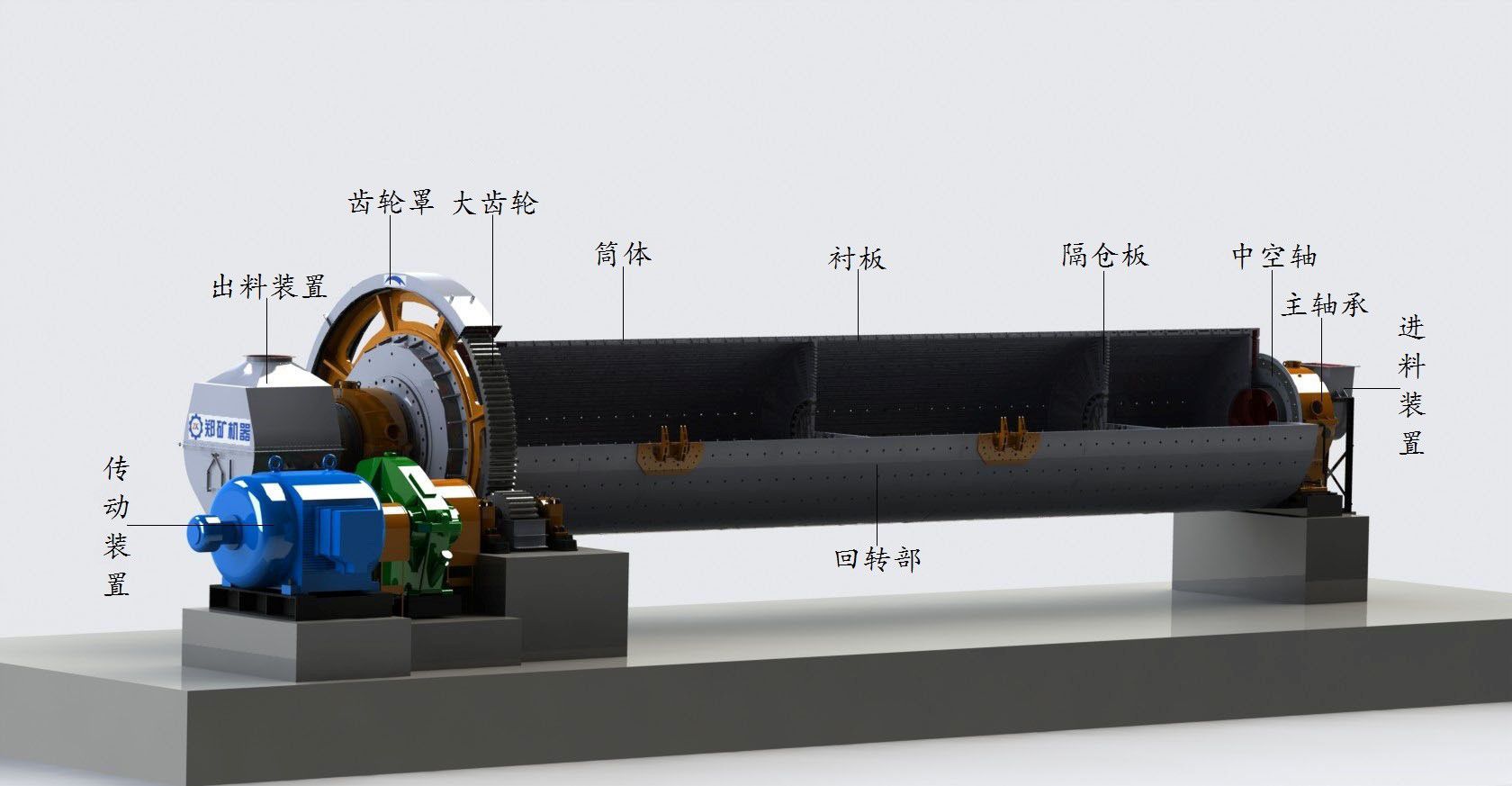

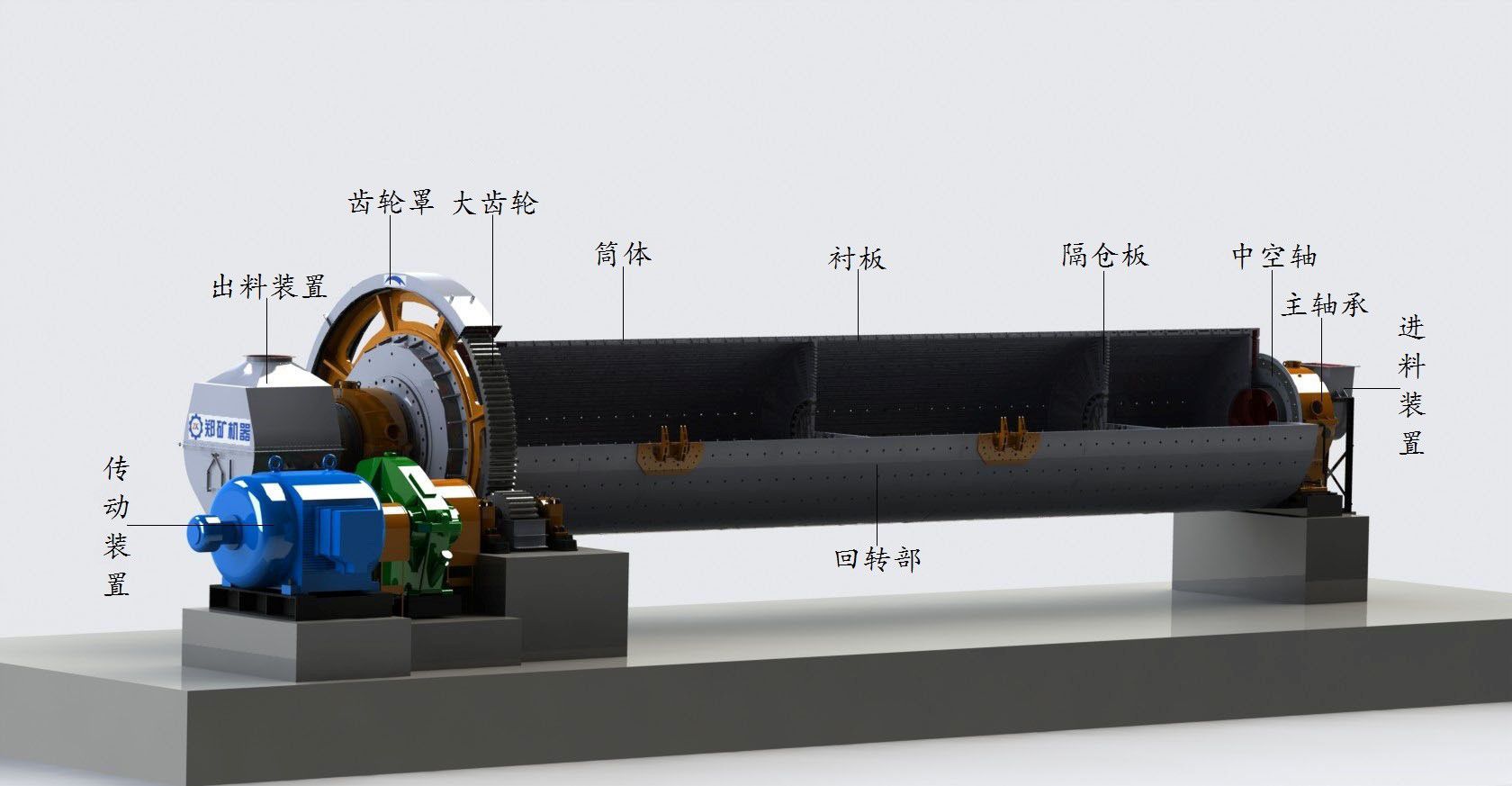

Adopts edge transmission method, the cement mill is generally 2 ~ 4 bin, material feeding device by feed screw evenly into the ball mill no. 1 warehouse, the warehouse has ladder lining board, built-in grinding media with different specs, cylinder rotation to generate centrifugal force will fall after grinding media to a certain height, to material impact and grinding; After finishing rough grinding of the material in warehouse 1, the material enters the next warehouse through the separate warehouse board. The warehouse is inlaid with corrugated lining plate or flat lining plate, with grinding medium, and the material is further grinded; The powder material is discharged through the unloading grate plate to complete the grinding work.

| 规格(m) | 产量(t/h) | 转速(r/min) | 研磨体(t) | 电机 | 减速机 | 重量(t) | ||

| 型号 | 功率(kW) | 型号 | 速比 | |||||

| Φ1.2x4.5 | 1.4 | 30.3 | 5 | YR250M-6 | 55 | ZD30-8 | 4.481 | 13.1 |

| Φ1.5x5.7 | 3.5 | 26.34 | 11 | JR127-8 | 130 | ZD40-7 | 4 | 25 |

| Φ1.83x6.4 | 6 | 23.9 | 18 | JR137-8 | 210 | ZD60-8 | 4.5 | 35.3 |

| Φ2.2x7 | 6.5 | 24.5 | 20 | JR138-8 | 245 | ZD60-8 | 4.5 | 37.2 |

| Φ2x9 | 9.5-10 | 23.88 | 31 | JRQ158-8 | 380 | ZD70-8 | 4.5 | 58.4 |

| Φ2.2x6.5 | 8--9 | 21.4 | 30 | JRQ158-8/YR630-8 | 380 | ZD70-9 | 5 | 46.2 |

| Φ2.2x6.5 | 14 闭路 | 21.4 | 30 | JRQ158-8/YR630-8 | 380 | ZD70-9 | 5 | 46.2 |

| Φ2.2x7 | 12 | 21.4 | 30 | JR158-8 | 380 | ZD70-9 | 5 | 54 |

| Φ2.2x7.5 | 13 | 21.4 | 32 | JR158-8 | 380 | ZD70-9 | 5 | 63 |

| Φ2.2x8 | 11--12 | 21.4 | 37 | JR158-8 | 380 | ZD70-9 | 5 | 65 |

| Φ2.2x9.5 | 14-16 闭路 | 21.4 | 43 | JR1510-8 | 475 | ZD70-9 | 5 | 70 |

| Φ2.2x13 | 16 | 20.3 | 55 | YR630-8/1180/Y100L-8 | 630/11 | JD630/ZS82.5-7 | 6.3/99.96 | 114.4 |

| Φ2.4x7 | 14-16 闭路 | 20.4 | 36 | JR1510-8 | 475 | JDX450 | 5 | 67.9 |

| 02.4x8 | 16-17 闭路 | 20.3 | 41 | JR1512-8/Y180L-8 | ||||

Cement ball mill because of its product size, shape, more suitable for the application of cement grinding, cement hydration and late strength improvement has a great advantage, so cement ball mill is widely used in cement grinding. There are 35 specifications and models of the cement ball mill product barrel diameter from 1.2m to 4.2m, supporting motors from 55KW to 3530KW, a single cement ball mill can meet the grinding of 1.4-87t cement products per hour, if used together with roller press, the capacity will be greatly improved.

1, high grinding efficiency, low energy consumption;

2, the fineness of the product is uniform, and the product is smooth;

3, small vibration, low noise, good sealing equipment, no dust spillover, clean environment, meet the requirements of environmental protection;

4, can design and manufacture special cement mill according to the user's different needs of grinding fineness and output.

Adopts edge transmission method, the cement mill is generally 2 ~ 4 bin, material feeding device by feed screw evenly into the ball mill no. 1 warehouse, the warehouse has ladder lining board, built-in grinding media with different specs, cylinder rotation to generate centrifugal force will fall after grinding media to a certain height, to material impact and grinding; After finishing rough grinding of the material in warehouse 1, the material enters the next warehouse through the separate warehouse board. The warehouse is inlaid with corrugated lining plate or flat lining plate, with grinding medium, and the material is further grinded; The powder material is discharged through the unloading grate plate to complete the grinding work.

| 规格(m) | 产量(t/h) | 转速(r/min) | 研磨体(t) | 电机 | 减速机 | 重量(t) | ||

| 型号 | 功率(kW) | 型号 | 速比 | |||||

| Φ1.2x4.5 | 1.4 | 30.3 | 5 | YR250M-6 | 55 | ZD30-8 | 4.481 | 13.1 |

| Φ1.5x5.7 | 3.5 | 26.34 | 11 | JR127-8 | 130 | ZD40-7 | 4 | 25 |

| Φ1.83x6.4 | 6 | 23.9 | 18 | JR137-8 | 210 | ZD60-8 | 4.5 | 35.3 |

| Φ2.2x7 | 6.5 | 24.5 | 20 | JR138-8 | 245 | ZD60-8 | 4.5 | 37.2 |

| Φ2x9 | 9.5-10 | 23.88 | 31 | JRQ158-8 | 380 | ZD70-8 | 4.5 | 58.4 |

| Φ2.2x6.5 | 8--9 | 21.4 | 30 | JRQ158-8/YR630-8 | 380 | ZD70-9 | 5 | 46.2 |

| Φ2.2x6.5 | 14 闭路 | 21.4 | 30 | JRQ158-8/YR630-8 | 380 | ZD70-9 | 5 | 46.2 |

| Φ2.2x7 | 12 | 21.4 | 30 | JR158-8 | 380 | ZD70-9 | 5 | 54 |

| Φ2.2x7.5 | 13 | 21.4 | 32 | JR158-8 | 380 | ZD70-9 | 5 | 63 |

| Φ2.2x8 | 11--12 | 21.4 | 37 | JR158-8 | 380 | ZD70-9 | 5 | 65 |

| Φ2.2x9.5 | 14-16 闭路 | 21.4 | 43 | JR1510-8 | 475 | ZD70-9 | 5 | 70 |

| Φ2.2x13 | 16 | 20.3 | 55 | YR630-8/1180/Y100L-8 | 630/11 | JD630/ZS82.5-7 | 6.3/99.96 | 114.4 |

| Φ2.4x7 | 14-16 闭路 | 20.4 | 36 | JR1510-8 | 475 | JDX450 | 5 | 67.9 |

| 02.4x8 | 16-17 闭路 | 20.3 | 41 | JR1512-8/Y180L-8 | ||||